With the in-depth promotion of Industry 4.0 and intelligent manufacturing, the industrial control gateway, as an “intelligent bridge” to realise the information interaction between internal and external information of industrial control systems, plays an irreplaceable role in enhancing the connectivity, security, and intelligence level of industrial control networks.

Functions of Industrial Control Gateways

Industrial control gateway usually contains a series of functions, including protocol conversion, data acquisition, remote management and security protection. In practical applications, it can connect industrial equipment using different communication protocols to achieve unified data acquisition and standardized processing. In addition, with built-in security mechanisms, it can effectively isolate the industrial control network from external threats, preventing malicious attacks and unauthorized access.

EG series industrial control gateway, is the edge computing gateway developed by IOTRouter. The products are fully self-developed, with guaranteed quality and supply. The products have passed the quality management system certification, EU CE certification, high and low temperature testing certification and many other certifications, and provide professional technical support.

The following advantages of using EG series gateway:

1. Ondersteuning Node-RED nul-code programmering

IoT commonly used logic and business can be realized through the form of drag and drop building blocks, saying goodbye to the traditional cumbersome cross-compilation, burn-in mode. Even if you are not satisfied, you can use the js language to secondary development, is also free of compilation directly run, the efficiency will be greatly improved.

2. Can be disconnected from the network to continue transmission

When the network is unstable or even interrupted, EG Edge Computing Gateway is able to cache local data and upload it immediately after the network is restored, ensuring the continuity and stability of the production process.

3. Uitgebreide interfaces en protocollen

Support 4G/Ethernet/WIFI triple-network communication, and more rich interfaces such as 2RS485/RS232/2DI/2DO/2CAN. Support docking a variety of mainstream PLC brands, a variety of IoT protocols, industrial protocols, support for data format customization, logic customization, private protocols niche protocols perfectly compatible.

4. Ondersteuning voor bediening op afstand

Ondersteuning voor externe configuratie, debuggen op afstand, diagnose op afstand, extern updateprogramma en andere functies.

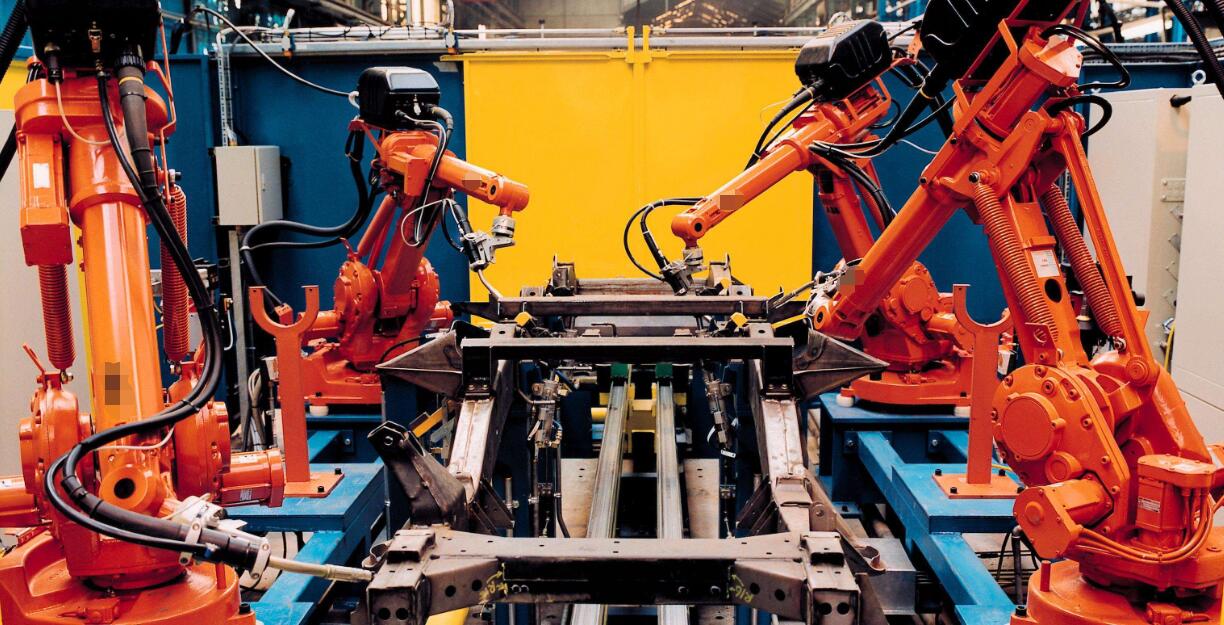

Application Scenarios in Intelligent Manufacturing

Taking the intelligent manufacturing production line as an example, there are a wide range of application scenarios for industrial control gateways. On a production line, various sensors, actuators, PLCs (programmable logic controllers) and other industrial control devices must work together through real-time, accurate data interaction. However, these devices often use different manufacturers’ communication protocols and data formats, posing a huge challenge to system integration and information exchange. In this case, the role of industrial control gateways becomes critical.

When deployed to the production line, the Industrial Control Gateway recognizes and accesses devices using various communication protocols. With the built-in protocol conversion function, it can convert data of different protocols into a unified standard format, such as OPC UA or MQTT, which facilitates data processing and analysis by the upper management system. In addition, the industrial control gateway can also collect real-time equipment operation status information and production data, and transmit these information to the cloud or local server through a high-speed and stable network, realizing visual monitoring and remote management of the production process.

Safety Functions of Industrial Control Gateway

In addition to operational functions, the Industrial Control Gateway also has powerful security protection functions. It effectively prevents external network attacks and virus invasion through measures such as whitelisting, firewall and intrusion detection system to ensure the safe and stable operation of the production line control system. In addition, the industrial control gateway also supports functions such as remote troubleshooting and firmware upgrading, which greatly enhances the maintainability and expandability of the system.

Kortom, de toepassing van industriële controlegateway op het gebied van intelligente productie verbetert niet alleen het automatiseringsniveau en de productie-efficiëntie van de productielijn, maar verbetert ook de veiligheid en beheersbaarheid van het systeem. Met de voortdurende ontwikkeling van Internet of Things technologie en de voortdurende verbetering van de industriële controlepoortfunctie, denk ik dat het een belangrijkere rol zal spelen in het toekomstige industriële controleveld.