IoT gateways can connect a variety of different types of IoT devices to achieve data transmission and communication between devices.IoT gateways have powerful data processing and analysis capabilities, and can process, analyse and store collected data to provide intelligent services for various applications.

In industrial production environments, the IoT gateway is a key component for inter-device communication and data transmission. It can connect various devices on the production line, such as sensors, actuators, PLCs, etc., to ensure real-time and accurate data transmission. At the same time, the Pasarela IoT can also pre-process and analyse the data to provide valuable information for higher-level applications.

Under the framework of Industry 4.0, IoT technology is the key to realising production automation, intelligence and networking.IoT gateway plays a central role in Industry 4.0 as a bridge between connecting devices and cloud platforms and application software.

Functional characteristics of IoT gateway in industrial production

1. Communication Between IoT Gateway and Devices

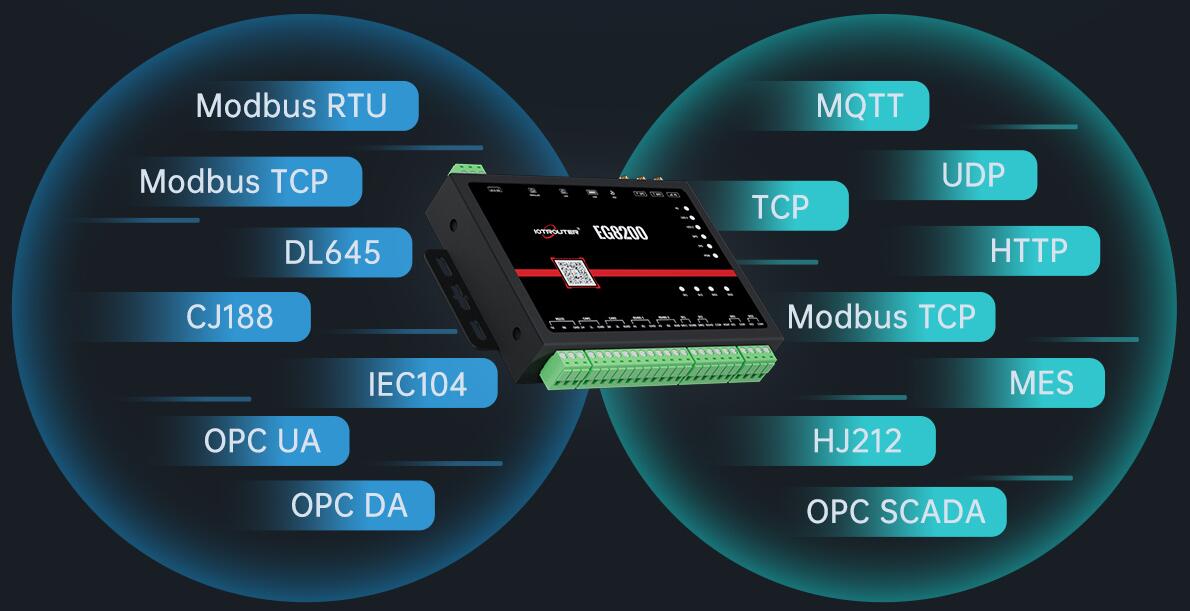

In industrial production, communication between devices is the key to ensure a smooth production process.IoT gateway supports a variety of communication protocols, such as MQTT, CoAP, etc., and is able to communicate with a variety of types of devices to ensure real-time data transmission and sharing.

2. Data Acquisition and Processing

The IoT gateway is able to collect a variety of data from the production line in real time, such as temperature, pressure, flow, and so on. By processing and analysing these data, it can monitor the operation status of the production line in real time, predict potential problems and intervene in advance to ensure stable and efficient production.

3. Remote Monitoring and Management

Through the IoT gateway, production managers can remotely monitor the operating status of equipment and understand the operation of the production line in real time. At the same time, the IoT gateway can also provide fault warning and fault diagnosis functions to help managers find and solve problems in time and reduce downtime.

4. Security and Reliability

In industrial production, the security and reliability of data is crucial.Pasarelas IoT are usually equipped with strong security mechanisms, such as data encryption and access control, to ensure the security of data during transmission and storage. In addition, IoT gateways are also equipped with high availability and fault tolerance to ensure that production processes can still run normally in the event of device failure or network disruption.

Application Cases of IoT Gateway in Industrial Production

Take the production line of an automobile manufacturing plant as an example, the plant introduced IoT gateway technology to realise the intelligent transformation of the production line. By connecting various devices on the production line through the IoT gateway, real-time communication and data transmission between the devices are realised. At the same time, the data processing and analysis functions of the IoT gateway are used to monitor and analyse the data on the production line in real time, so that problems in the production process can be identified and adjusted in a timely manner. This not only improves production efficiency and quality, but also reduces production costs and failure rates.

Related Products

The EG8000 gateway series is equipped with node-red system, which can achieve 0 code, visualisation and drag-and-drop programming. It allows you to easily connect hardware devices such as plc, industrial control machine, etc., while supporting various communication transmission protocols. It allows you to send the data to the cloud server in a specified format after the gateway has processed it, thus reducing the server load, and even allows you to use the LAN to continue sending commands to plc and other logic control units in the event of a disconnection.

IoT gateway plays an important role in industrial production. It is not only a bridge connecting devices to cloud platforms and applications, but also the key to automation, intelligence and networking of production. By introducing IoT gateway technology, enterprises can improve production efficiency and quality, reduce costs and failure rates, and achieve sustainable development. Meanwhile, with the continuous development and popularisation of IoT technology, the application of IoT gateway in industrial production will become more and more widespread. It can connect a variety of industrial equipment, achieve communication and data transmission between equipment, and provide strong support for the intelligence of industrial production. In the future, with the continuous progress and innovation of technology, the IoT gateway will play a more important role in industrial production and promote the intelligent and efficient development of industrial production.