In modern industrial control systems, it is often necessary to convert CAN bus data into the data format required by the 485 communication protocol. This process involves data parsing and conversion, and the application of new technologies can greatly improve the efficiency and reliability of data conversion. The corresponding analysis of CAN to 485 data is an important technical issue, which will be discussed below.

CAN (Controller Area Network) bus is a serial bus communication protocol commonly used in vehicle systems, industrial control systems and other fields. The 485 communication protocol is a common communication protocol in the industrial field and is used to transmit data in long-distance environments. Since the data formats of the two communication protocols are different, data conversion is required. Among them, the CAN bus data is transmitted in the form of frames, and the 485 protocol needs to convert the data into a continuous bit stream. Therefore, the corresponding analysis of CAN to 485 data is particularly important.

For the corresponding analysis of CAN to 485 data , the traditional approach is to use a special conversion chip or module to achieve data format conversion through hardware circuits. Although this method can meet basic conversion needs, it has problems such as high cost, high power consumption, and poor reliability in large-scale applications. Applications based on new technologies, especially software-defined data conversion technology, can solve these problems well.

Software-defined data conversion technology refers to the conversion of data formats through programming rather than relying on hardware circuits. This technology has the advantages of low cost, low power consumption, and strong flexibility, and is especially suitable for scenarios in modern industrial control systems that require high data conversion efficiency and reliability. In the corresponding analysis of CAN to 485 data, the software-defined data conversion technology can realize the corresponding conversion with the 485 communication protocol by analyzing and reconstructing the CAN bus data.

Specifically, software-defined data conversion technology usually uses high-performance microprocessors or digital signal processors to convert data formats. Through programming to realize data analysis, reconstruction and verification, CAN bus data can be effectively converted into a data format that conforms to the 485 communication protocol. Moreover, software-based data conversion technology can also support more communication protocols through firmware upgrades, thereby improving system flexibility and scalability.

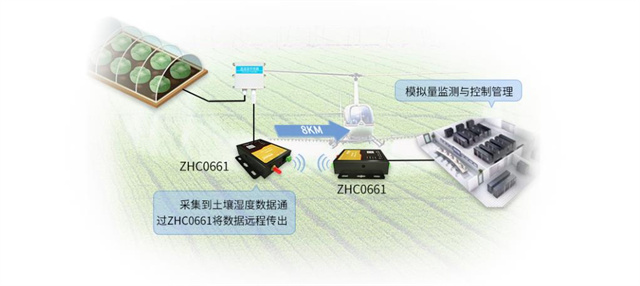

In addition to software-defined data conversion technology, there are also some new technology applications that can further improve the corresponding analysis efficiency and reliability of CAN to 485 data. For example, data analysis algorithms based on deep learning can improve the accuracy of analysis by learning data characteristics; applications based on Internet of Things technology can achieve remote monitoring and configuration, improving the manageability and maintainability of the system; block-based The application of chain technology can improve the security and credibility of data and prevent data tampering and forgery.

To sum up, converting CAN to 485 data is an important technical issue, and the application of new technologies can greatly improve the efficiency and reliability of data conversion. Software-defined data conversion technology is an important part of it. It can realize data format conversion through programming and solve the problems of traditional hardware conversion methods. You may also need to understand the interpretation of the 485 to CAN protocol .