Factory energy data collection and real-time monitoring is an important part of a factory’s Energy Management System (EMS), which is essential for improving energy efficiency, reducing operating costs and optimising production processes. By adopting a variety of methods and tools to comprehensively and accurately collect all kinds of energy consumption data and monitor factory energy usage in real time, it can help factories better understand the energy consumption situation, discover energy-saving potentials, and formulate effective energy-saving measures. At the same time, ensuring data accuracy and security is also an important prerequisite for implementing real-time monitoring.

Energy Data Collection Methods

In order to comprehensively and accurately collect a variety of energy consumption data, we need to use a variety of methods and tools:

1. Instrument Reading: Use various energy measuring instruments (such as power meters, water meters, gas meters, etc.) to directly read raw energy consumption data. Selecting high-precision and reliable meters is the key.

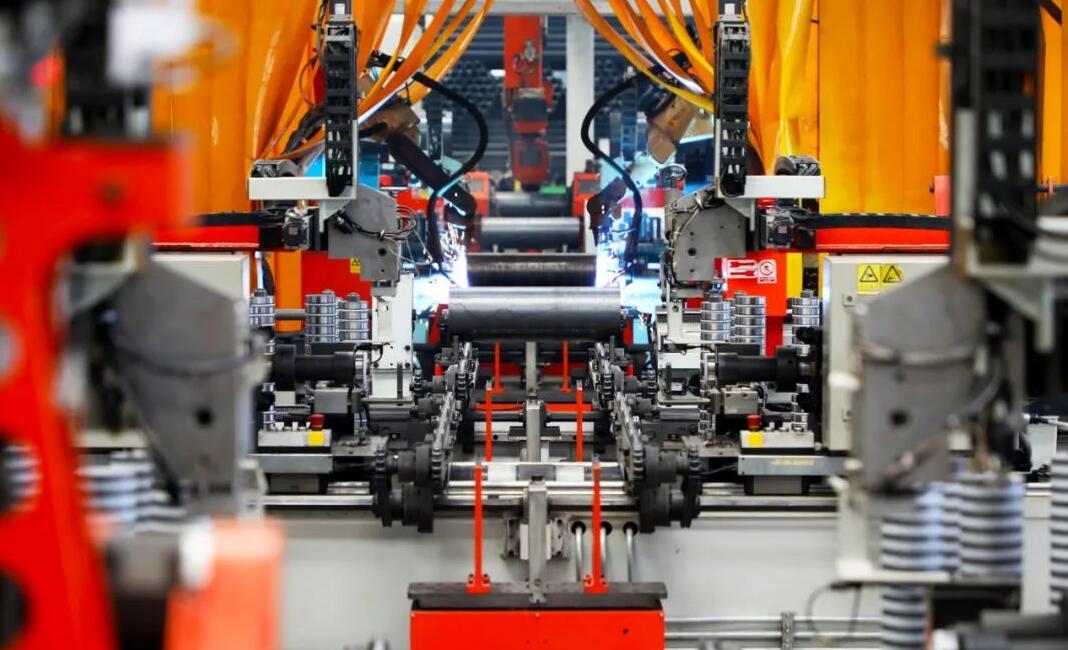

2. Intelligent Devices And Sensors: Real-time monitoring of various energy usage in the factory by installing intelligent devices and sensors. These devices can detect various parameters such as temperature, pressure, flow rate, etc.

3. Data Gateway And Communication Protocol: Data gateway is used to collect data from various devices and meters and transmit the data to the central management system through a unified communication protocol (e.g. Modbus).

4. Data Analysis And Processing: Processing, analysing and mining the collected raw data to extract valuable information, such as energy intensity and equipment energy efficiency.

5. Combination Of Automation And Manual Collection: For some specific energy consumption data, it may not be possible to collect them in an automated way. In this case, it can be combined with manual collection to ensure the integrity of the data.

Real-time Monitoring Of Energy Use

1. Real-time Data Display: Through the visual interface or data platform, real-time display of the factory’s energy use. Including total energy consumption, energy consumption of each region or equipment and other key indicators.

2. Abnormality Detection And Alarm: Establish an abnormality detection mechanism to monitor abnormal fluctuations in energy usage data in real time. Once anomalies are detected, timely alarms are issued so that measures can be taken quickly.

3. Trend Analysis And Prediction: Using real-time data, trend analysis is carried out to predict future energy demand. Provide strong support for decision-making, help factories optimise energy use. 4. Dynamic scheduling and optimisation.

4. Dynamic Scheduling And Optimisation: According to the real-time monitoring of energy use, dynamic scheduling and optimisation. Adjust equipment operating parameters, start or stop the relevant equipment, etc., to achieve efficient use of energy.

5. Remote Monitoring And Mobile Access: Through the IoT technology and cloud platform, it can realise remote monitoring of energy usage in the factory. At the same time, it provides mobile access function, which is convenient for managers to understand the energy usage situation anytime and anywhere.

Case Study

Taking a chemical plant as an example, it collects various energy consumption data comprehensively and accurately and monitors the energy usage of the plant in real time.

Firstly, the chemical plant adopts high-precision sensors and meters, such as electricity, water and gas meters, to monitor various energy consumption in real time. These sensors and meters are connected to the data acquisition system by wired means to ensure stable data transmission.

To ensure the accuracy and consistency of the data, the chemical plant adopts an IOTROUTER gateway for data acquisition, data cleaning and pre-processing, which filters and denoises the raw data and removes outliers and repetitive data. At the same time, the chemical plant has also established a real-time monitoring platform to visualise various energy consumption data in the form of charts, curves, etc., so as to facilitate managers’ real-time understanding of energy usage.

Through the real-time monitoring platform, the chemical plant has realised dynamic monitoring and alarm functions for energy use. When the energy consumption is abnormal or the equipment fails, the system will automatically alarm and remind the manager to deal with it in time. In addition, the plant analyses and optimises the real-time monitoring data in the light of the production plan and actual demand, and formulates a series of energy-saving measures, such as adjusting the production process and replacing high-efficiency equipment.

Through these measures, the plant has achieved the goal of comprehensively and accurately collecting various energy consumption data and monitoring the plant’s energy use in real time, improving energy use efficiency and management levels. At the same time, the chemical plant has reduced energy consumption and costs, contributing to the sustainable development of the enterprise.

Accurate and real-time energy data collection and monitoring is a key aspect of plant energy management. Measures such as reasonable selection of sensors and meters, optimising the layout, and setting the appropriate data collection frequency and cycle ensure the comprehensiveness and accuracy of the data. At the same time, a real-time monitoring system is used to display energy usage in real time, perform anomaly detection and alarm, trend analysis and prediction, dynamic scheduling and optimisation, as well as remote monitoring and mobile access. This will help the plant to improve energy efficiency, reduce operating costs and achieve sustainable development goals.